News: Drew Estate Dedicated to Expansion, Maintaining Quality Control

14 Apr 2014

Last week Patrick S and I were on location in EstelÃ, Nicaragua, to attend Drew Estate’s Cigar Safari. In the coming days we’ll have lots of content to share with you—including dozens of photos, a new premium tobacco being grown in Florida, and a behind-the-scenes look at “DE2.†But today I’ll start with the high-level highlights about our host.

It’s worth pointing out that Drew Estate is now producing around 100,000 cigars per day. To put this in perspective, even though there’s no such thing as the “typical†cigar factory, the median for cigar factories could be considered to be around 35,000 cigars per day.

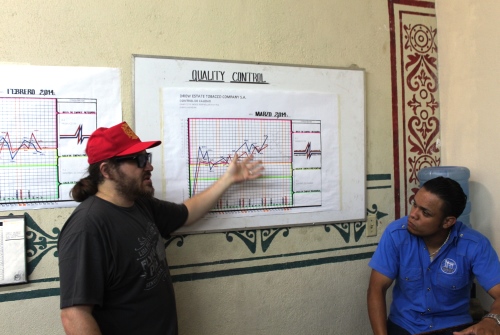

Jonathan Drew admitted to the challenges associated with such high production. Drew Estate needs to hire more supervisors and more employees for the quality control room. Currently, the company is purposefully rejecting a higher percentage of cigars at each level of the process—a decision that’s less than optimal for profit maximization. But it’s clear Drew Estate will not compromise on quality control.

Eventually, as the organization acclimates to its accelerated levels of production, the percentage of rejects is expected to drop to an acceptable level. This acclimation includes promoting more standouts to supervisor rolls, hiring more staff, and even knocking down walls in the factory to improve flow and reduce accidental cigar damage.

Jonathan Drew seems to be grappling with the reality that his role is to make business decisions for the company. He is more of a corporate executive than a cigar blender or tobacco man. Nicholas Melillo, on the other hand, is redoubling his efforts in many areas he shared with Steve Saka (before Saka’s departure). These include tobacco purchases, overseeing the aging and fermentation processes, and working on blending.

Willy Herrera will be expanding his Herrera Estelà line with a Lancero. We saw the prototype on Drew Estate’s main rolling floor. He also has a whole new line in the works called Herrera Norteño, which will make use of Mexican tobacco. Willy continues to be an imposing, soft-spoken presence.

Part of Drew Estate’s expansion includes ensuring enough room to age cigars post-production before they are shipped. Interestingly, the room currently used for this purpose is colder than you might expect. That’s because Drew Estate has found that cold aging is similar to the “low and slow†rule of barbeque. Aging takes longer at a colder temperature, but the end result is superior. However, with Liga 9 in particular, they’ve found less aging produces a better result, so that blend is spending less time in this room.

Here are a few other nuggets of information about Drew Estate that are worth mentioning:

— Despite rumors that the company purposefully depresses production of Liga 9 to drive up price, Jonathan Drew once again assured us that he is making as much of the blend as possible. The key constraint is the availability of certain tobaccos. Again, the theme here is that quality will not be compromised.

— Drew Estate considers its main competitors to be Arturo Fuente, Davidoff, General Cigar, and Altadis—not small boutique brands.

— The cigar bubble burst of the late ’90s was, in a way, a blessing for Drew Estate. Falling demand meant the up-and-coming company had access to better tobacco than they might have otherwise been able to purchase.

Later on this week, I’ll report specifically on Drew Estate’s new pre-industry facility, which they’ve dubbed “DE2,†and what the enormous building means for the company. For now, I welcome your comments and questions.

photo credit: Stogie Guys

Patrick Ashby

Co-Founder & Editor in Chief

Patrick Ashby

Co-Founder & Editor in Chief Patrick Semmens

Co-Founder & Publisher

Patrick Semmens

Co-Founder & Publisher George Edmonson

Tampa Bureau Chief

George Edmonson

Tampa Bureau Chief

Aaannddd… this is why I love this site. Great insight into one of my fav cigar operations!